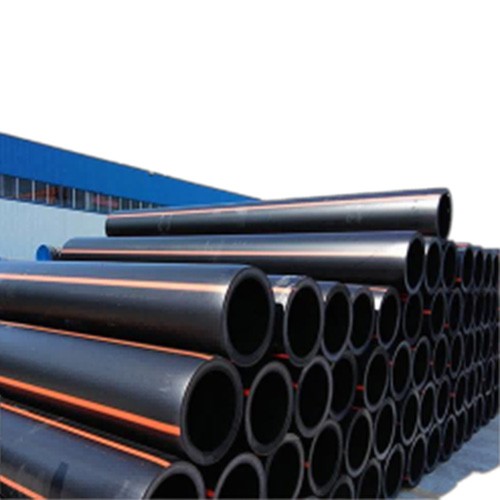

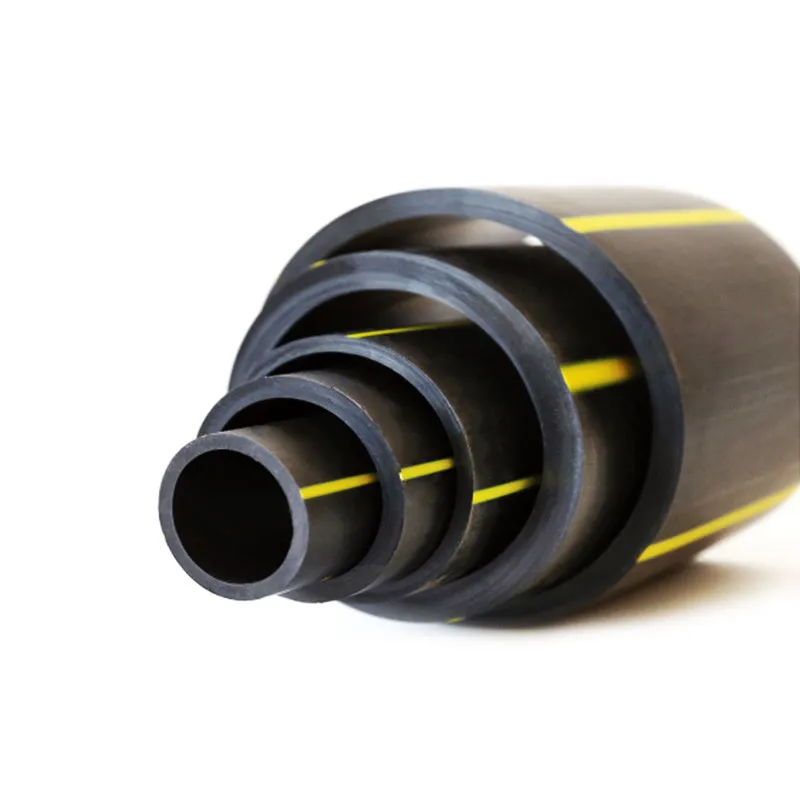

HDPE Pipe For Mining

Desu polyethylene (HDPE) pipe’s unique mechanical properties, safety and reliability have made HDPE (High-density polyethylene) piping systems to be the he best choice for mineral and waste transfer in the mining industry.

Description of HDPE Mining Pipe:

Security, reliability and abrasion resistance are the three most important factors for the mining pipes. The pipe must be Chemical Resistance, rustproof, break-resistant and corrosion-free. HDPE piping system ensures safe usage while having high economic benefits.

HDPE pipes are more and more popular in mining pipes. They are not only easy to install, but also resistant to acid and alkali corrosion and abrasion The service life is much longer than other pipelines. PE pipe for mining works is used for mortar pipe ,drainage pipe, gas drainage pipe, positive and negative pressure air pipes etc.

Advantages of the HDPE Mining Pipe and Fitting:

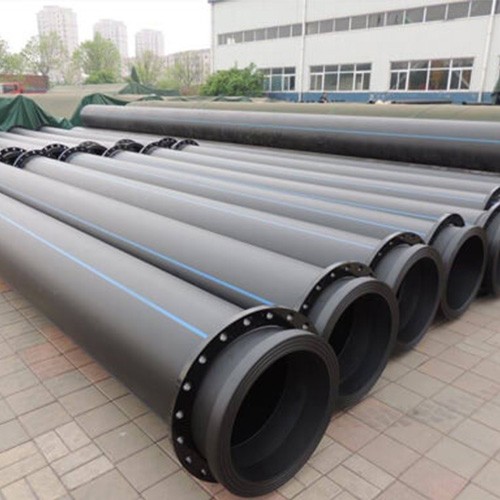

No leakage with a reliable connection: The polyethylene pipe system is connected butt fusion or electrofusion, and the strength of the joint is higher than that of the pipe body. The HDPE pipe and other pipes are connected by flange, which is convenient and quick.

No leakage with a reliable connection: The polyethylene pipe system is connected butt fusion or electrofusion, and the strength of the joint is higher than that of the pipe body. The HDPE pipe and other pipes are connected by flange, which is convenient and quick.

Chemical Resistance: Polyethylene is an inert material. HDPE pipes are resistant to erosion by various chemical media except for a few strong oxidants. Chemical substances present in the soil will not cause any degradation to the pipe, HDPE pipe is the first choive in harsh chemical environments.

- Good wear resistance: The wear resistance of HDPE pipe is 4 times of steel pipe as per the comparison test results. In the field of mud transportation, HDPE pipes have better wear resistance than steel pipe, which means that HDPE pipes have longer service life and lower cost.

- Pressure Surge Resistant: HDPE pipe can withstand high external loads and high internal pressure surges. Its flexible nature expands with pressure surges increases the life of the pipeline and reduces maintenance costs.

- Low cost: HDPE pipe is extremely cost-effective due to its low maintenance cost and leak-free joints. It can withstand high external and internal pressure loads, thereby reducing any associated maintenance costs and extending the overall life of the pipeline.