Steel Wire Reinforced HDPE Composite Pipes

The Steel wire reinforced thermoplastics(PE) composite pipe is a new type of double-sided anti-corrosion pressure pipe. It is composed of a tubular steel wire mesh wound welded as a reinforced skeleton, and embedded in the middle of the thermoplastic pipe wall. which is widely used in portable water, oil fields, power plants, chemicals, petrochemical enterprises, municipal gas, seawater pipelines and other fields.

Performance of HDPE Steel Framed Pipes

Enhanced Structural Strength: The steel frame within these pipes provides superior mechanical strength and rigidity, allowing them to with stand higher internal andexternal pressures compared to standard HDPE pipes.

Enhanced Structural Strength: The steel frame within these pipes provides superior mechanical strength and rigidity, allowing them to with stand higher internal andexternal pressures compared to standard HDPE pipes.

Corrosion Resistance: The outer HDPE layer offers excellent resistance to corrosionand chemical attacks, protecting the steel frame and ensuring a longer lifespan of thepipe.

Flexibility and Crack Resistance: Despite the steel reinforcement, these pipes maintaina degree of flexibility, which is characteristic of HDPE. This flexibility aids in resistance to environmental stress cracking.

Abrasion Resistance: The inner HDPE laver provides a smooth surface that minimizes wear and tear due to abrasive materials passing throuah, makina them ideal for transporting solids.

Temperature and lmpact Reslience: These pipes can operate effectively in a range of temperatures and are also resistant to impacts, which is crucial for harsh environmental conditions.

Applications of HDPE Steel Framed Pipes

Industrial Applications: ldeal for transporting abrasive materials in industries such asmining, where durability and resistance to wear are essential.

Municipal Water and Sewer Systems: Used in pressurized water supply networks and sewage systems due to their high strength and corrosion resistance.

Oil and Gas Industry: Suitable for transporting oils, gas, and other hydrocarbons especially where a combination of strength and chemical resistance is needed.

Marine and Underwater Pipelines: Their resistance to corosion and high pressure makes them suitable for underwater pipelines and marine applications.

Agricultural lrrigation: The pipes’ durability makes them suitable for large-scale irrigation systems, especially in areas with harsh environmental conditions.

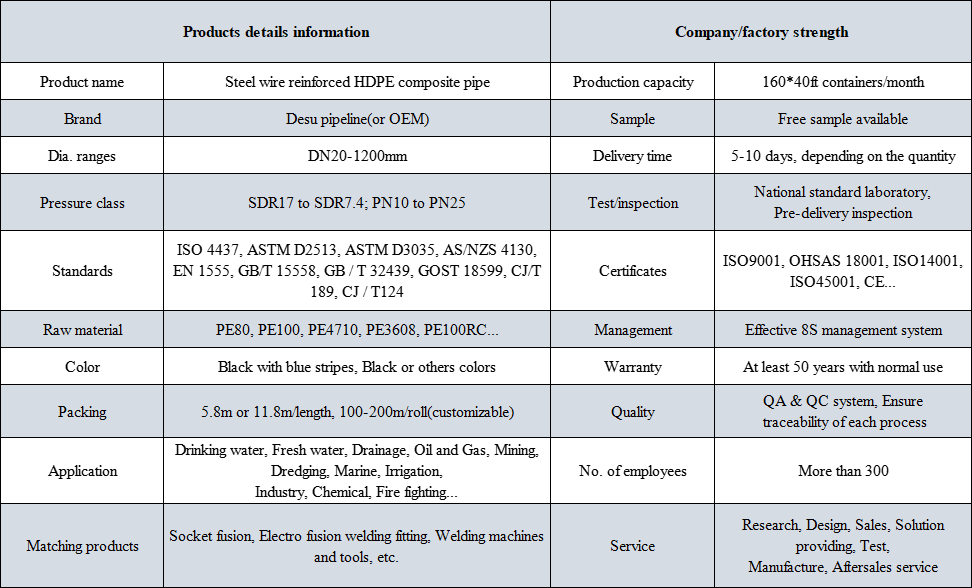

Product Description

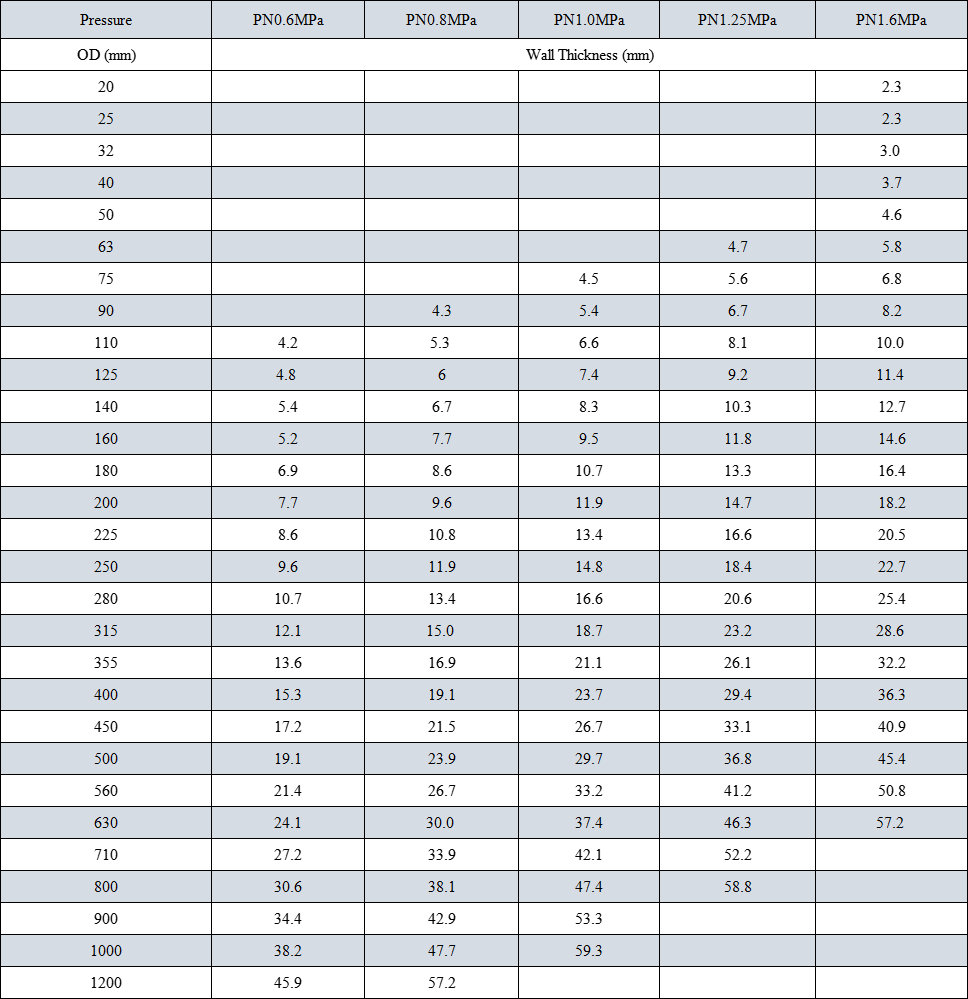

Specification