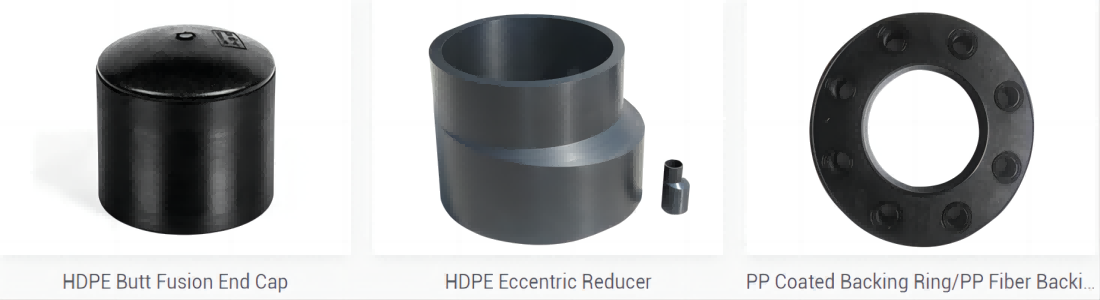

HDPE Butt Fusion fittings

Product Description

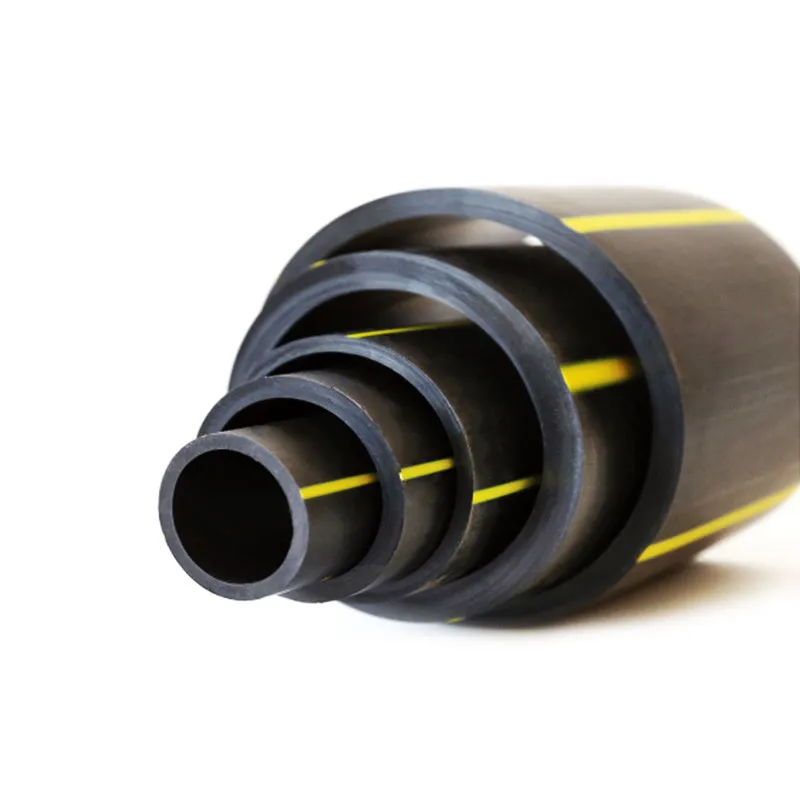

Butt fusion is the most commonly used fusion method for HDPE pipes, and HDPE butt fusion pipe fittings are the most commonly used fittings for HDPE piping systems. All PE butt fusion fittings are made of PE100 material. The outer diameter of HDPE butt welded pipe fittings should be exactly the same as the HDPE pipe. Use the HDPE pipe butt welding machine to fuse the two ends at a certain temperature and time, then remove the heating plate and bond the two ends tightly together under a fixed pressure until it cools.

Performance of HDPE Butt Fusion Fittings

- No leakage: The connection is reliable, and the strength of the butt fusion interface between the pipe fitting and the pipe is as good as the pipe itself, and has the same life expectancy.

- Non-toxic: do not scale, do not breed bacteria or contain heavy metal additives.

- Wear resistance: It has excellent wear resistance. Since its inner wall is lubricated and the friction coefficient is extremely low.

- Corrosion resistance: PE pipe fittings are made of inert materials. They has good corrosion resistance to galvanic corrosion such as electrical current, salts in the soil, acids and water vapor. The pipe fittings can be used immediately without any anti-corrosion treatment.

- Shock resistance: good flexibility, high impact strength, strong shock resistance, can be used in many applications.

- Reduce project costs: The welding process at the interface is simple, the connection of pipe fittings is fast and convenient, and the total project cost is low.

- Light weight: They are convenient to transport and install with long service life.

- Ease of installation: The but fusion process is relatively straight forward and, once completed,requires litle maintenance, saving time and resources in both installation and long-term operation.

Applications of HDPE Butt Fusion Fittings

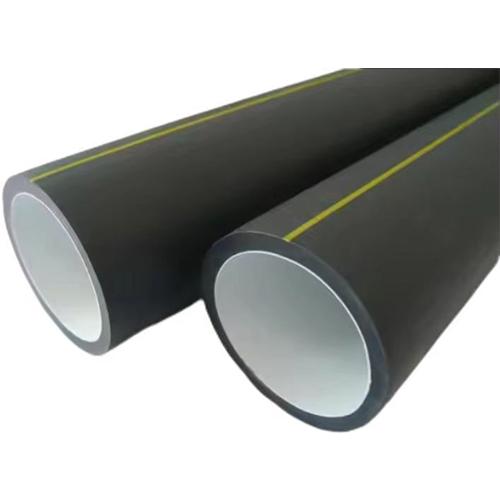

Water Supply Networks: These fittings are widely used in the construction and maintenance of municipal and industrial water supply systems.

Water Supply Networks: These fittings are widely used in the construction and maintenance of municipal and industrial water supply systems.

Gas Distribution Systems: The integrity of the joints makes them ideal for gas pipelines, where leak-proof connections are critical.

Chemical Transport Lines: Their chemical resistance properties make them suitable for pipelines transporting various industrial chemicals.

Mining and Dredging Applications: The robustness and durability of these fittings are beneficial in the harsh conditions of mining and dredging operations.

Sewage and Waste water Systems: HDPE Butt Fusion fittings are used in sewage and waste water pipelines due to their resistance to corrosion and biological growth.

HDPE Butt Fusion welding Fittings