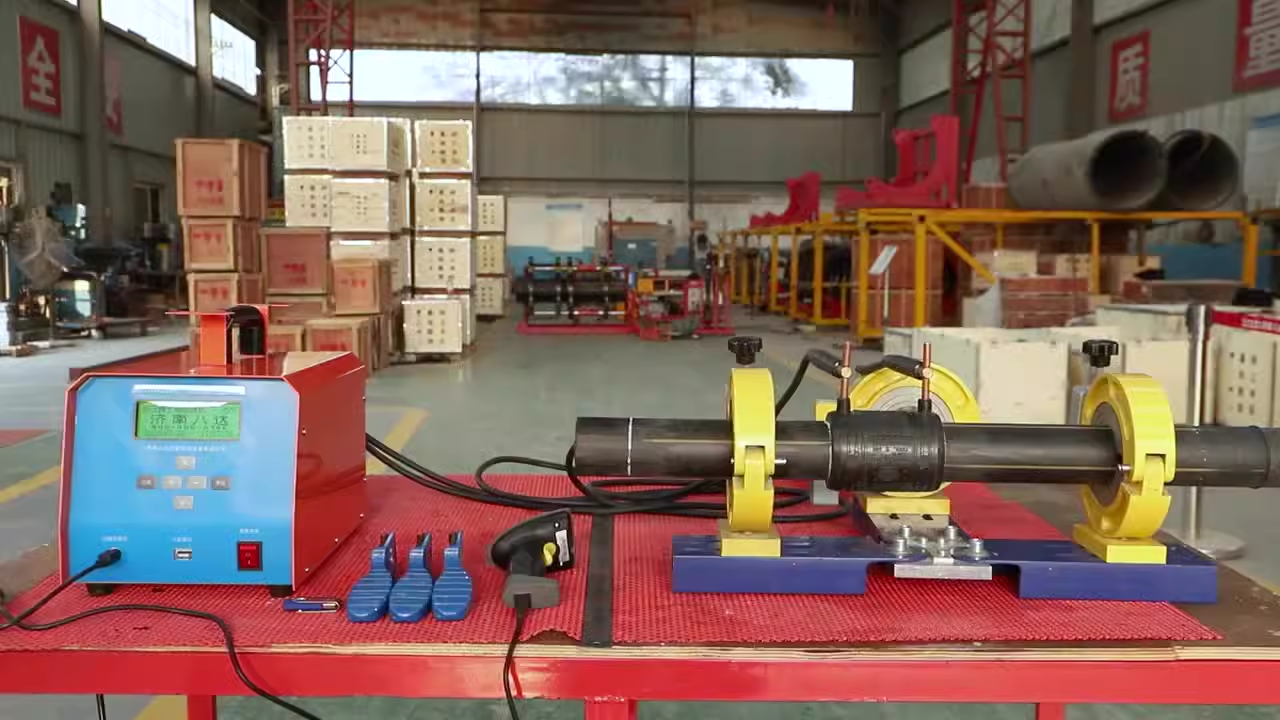

HDPE Electrofusion Fusion Fittings

Product Description

HDPE Electro-Fusion Fittings are cuting-edge components in the realm of high-density polyethylene piping systems, renowned for their precision and efficiency in creating secure joints, Utlizing advanced electro-fusion technology, these fitings provide a seamless and durable connection for various applications.

Performance of HDPE Electro-Fusion Fittings

Precision Fusion Technology: Electro-fusion involves melting the HDPE material atthe joint interface using an electric current, resulting in a homogenous andextremely strong connection.

Precision Fusion Technology: Electro-fusion involves melting the HDPE material atthe joint interface using an electric current, resulting in a homogenous andextremely strong connection.

Leak-Free Joints: The fusion process ensures a leak-free seal, making these fittings ideal for applications where water or gas containment is critical.

Chemical Resistance: HDPE Electro-Fusion Fittings exhibit excellent resistance tochemicals, enhancing their suitability for a range of industrial applications.

Corrosion Resistance: The fittings are impervious to corrosion, providing long-term durability in various environmental conditions.

Fast and Efficient lnstallation: Electro-fusion allows for quick and efficient fittings installation, reducing downtime and labor costs.

Applications of HDPE Electro-Fusion Fittings

Municipal Water and Gas Distribution: Widely used in the construction and maintenance of water and gas distribution networks in urban and rural areas.

Municipal Water and Gas Distribution: Widely used in the construction and maintenance of water and gas distribution networks in urban and rural areas.

Industrial Piping Systems: Suitable for industrial applications requiring reliable and durable connections, such as in chemical plants and manufacturing facilities.

Mining Operations: The corrosion resistance and durability make these fittings valuable in mining operations, handling the transport of minerals and water.

Landfill Leachate Collection Systems: Used in the construction of landfill leachate collection systems due to their resistance to chemical exposure.

Geothermal Heating Systems: Applied in geothermal heating systems, where the fittings' ability to withstand temperature variations is crucial.